For all who value individuality at its best:

Laser cutting for aluminosilicate glass

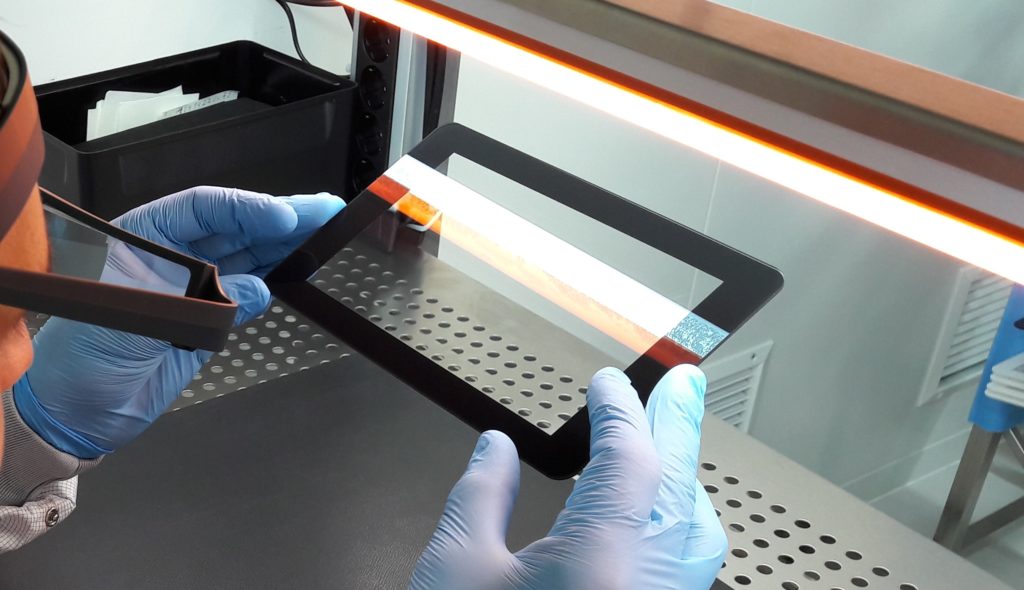

The new developed process enables the tolerance-free, non-abrasive cutting of aluminosilicate glasses after the chemical hardening process of substrates by short pulsed picosecond lasers.

Basis is the Gorilla® glass from Corning. The generated glass cut edge is extremely precise and clean.

The process is ideal for sample numbers and volume projects due to low initial costs and very short lead times. Due to the tolerance-free cut, the glass is especially suitable for the integration in plastic injection molded housings or milled aluminium frames.

Your advantages with our Corning Gorilla Glass at a glance

- Improved residual strength after use

- High resistance to scratches and sharp contact damage

- Best surface quality, absolutely flat (+/- 50 microns) due to manufacturing in the – fusion overflow process

- Thinner glasses = less weight

- Better electrical properties = better touch performance

- Less defects, better optical performance (pure white glass, no color shift)

- Availability in thicknesses of 0.4 – 2.0 mm

- Available as AG (Anti-Glare), AR (Anti-reflective) with AF (Anti-Fingerprint) and AM (Anti-Microbacterial)

- No relevant tolerance deviations (+/- 50 μm) during laser cutting