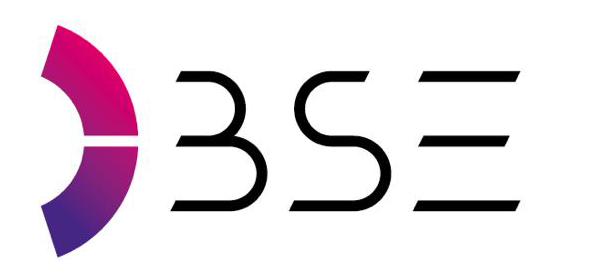

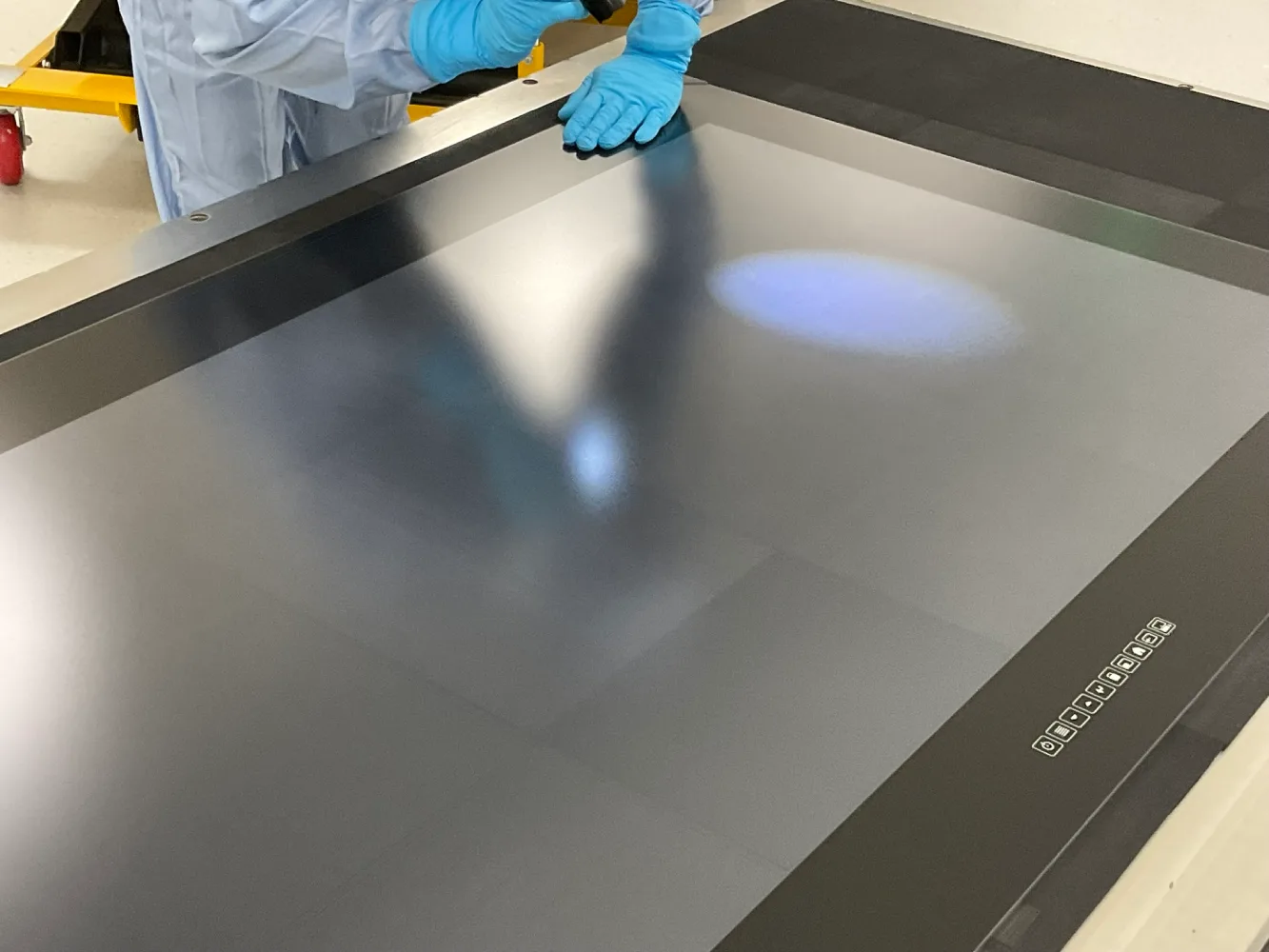

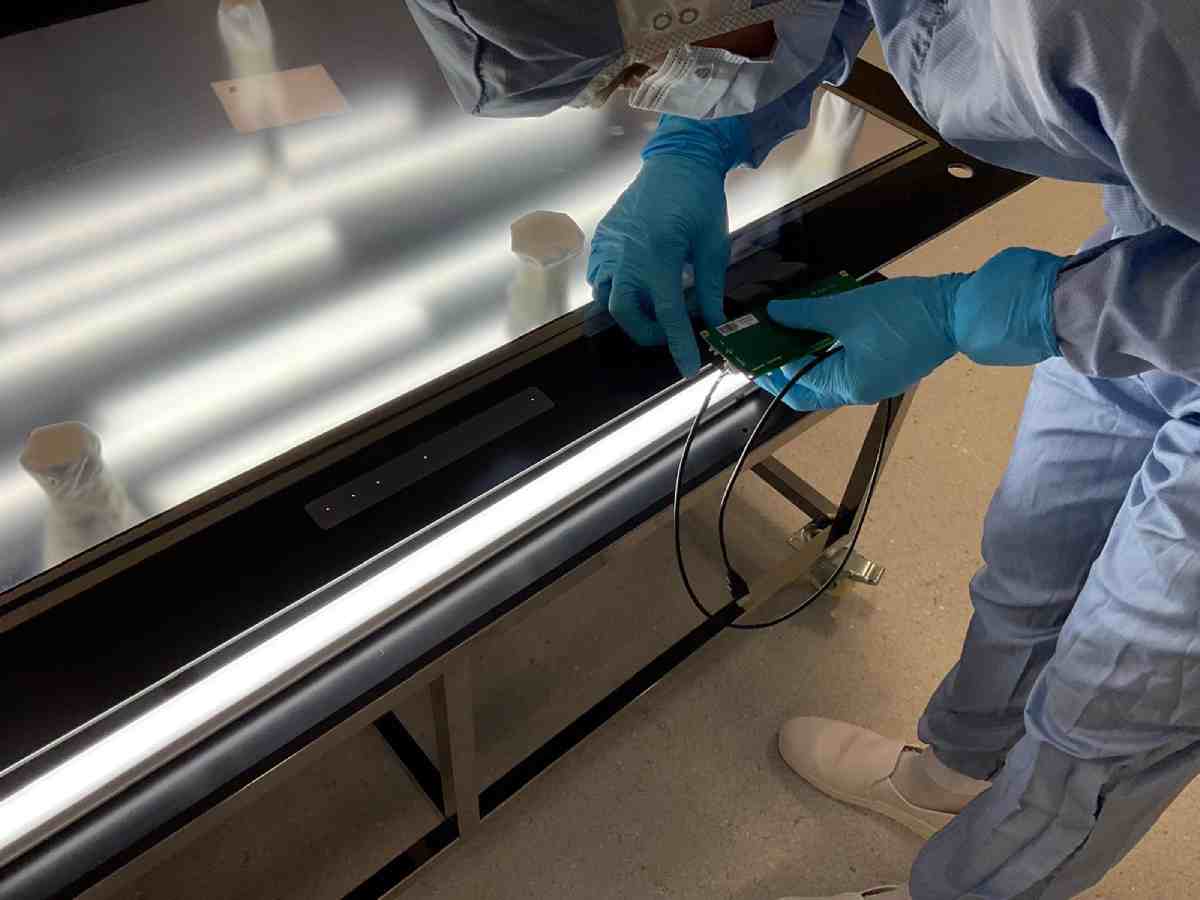

Optical Bonding (OCR / OCA)

Optical Bonding verbindet Display und Coverglas dauerhaft – für höchste Ablesbarkeit, geringere Reflexionen und eine robuste, langlebige Baugruppe. Je nach Anwendung setzen wir OCR oder OCA ein und steuern den gesamten Prozess (Vorbereitung, Bonding, Aushärtung, Prüfung) unter kontrollierten Bedingungen.

- Blasenfrei durch Vakuum- & Reinraumprozesse

- OCR bis 86″ · OCA bis 31,5″